Testing Services

Flexible Circuit Technologies (FCT) performs appropriate testing services for the given products that we produce and/or will employ custom customer required testing procedures, per requirements.

This includes prototype, first article, and production testing as required to meet customer requirements.

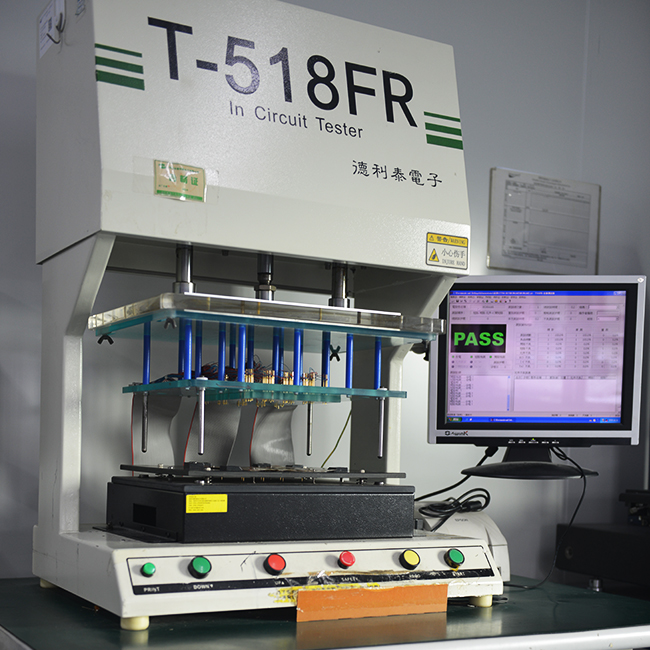

For bare flex the most common testing is open/short testing near the final stages of production. Most often this requires the development of a test fixture in order to maximize speed and lower costs, by testing full panels verses testing individual circuits.

For certain products an AOI (Automated Optical Inspection) test may be incorporated during production process.

For flex circuit assemblies the most common test is an electrical test of openings, shorts, on, off, or further customized testing procedure dependent on customer specification and requirements.

For more advanced sub-assemblies and for box builds, FCT can work with the customer to develop specific functional testing up to and including real-time access to online test results.

FCT's Test Engineer team is highly experienced in performing electrical and functional testing, firmware/software loading, programming and testing, and further is adept at designing and developing custom automated test equipment that is often required to meet large scale production programs.