Manufacturing, Assembly, Product Box Builds

Flexible Circuit Technologies’ core business is flexible circuit design and production which is aimed at providing our customers with high quality production parts at competitive prices. From small to high volume programs, we are set up to meet your Flex/Rigid Flex/Flexible Heater needs and further; your circuit assembly, product module to complete product box build.

Flexible Circuit Technologies’ core business is flexible circuit design and production which is aimed at providing our customers with high quality production parts at competitive prices. From small to high volume programs, we are set up to meet your Flex/Rigid Flex/Flexible Heater needs and further; your circuit assembly, product module to complete product box build.

Circuit Manufacturing

FCT's three Flex/Rigid Flex/Flex Heater facilities include our brand new FCT Zhuhai facility: 485,000 sq. ft. complex in Zhuhai China, FCT Zhangzhou: 170,000 sq. ft. facility in Zhangzhou, China and FCT Jiangmen, our 60,000 sq. ft. facility in Jiangmen, China.

Our multiple facility approach allows us to offer significant capacity, extensive capabilities, and the flexibility to meet broad customer requirements while able to meet low to high volume needs.

Unless specified by our customers, FCT most often utilizes IPC approved, Asia equivalent materials that helps our customers to attain excellent savings while not giving up on performance. We also utilize customer specified materials when/if needed.

Given our superior design expertise, FCT develops high quality products that are produced at high yields leading to improved overall costs.

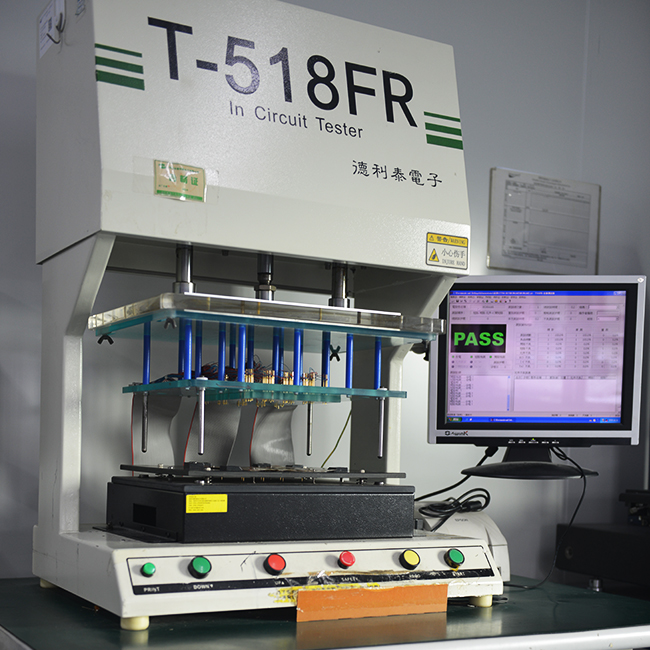

EMS/Assembly Services

FCT’s Asia based headquarters is located in Shenzhen, China. This 85,000 square foot facility is home to our China based Management team, Program Managers, Customer Support staff, and world class Assembly facility.

Our assembly facility offers:

- Seven complete SMT lines

- 100K and 10K Clean Rooms

- 9 modern Electronic Workshops

- Reliability Lab

- Testing Services

- Dedicated workshops for specific customers in support of meeting high-volume programs and dedicated workshops that are set up for high mix - lower volume programs.

Assembly Capabilities Include:

- Full SMT lines

- Leading expertise in placement of components onto flex

- Hot-Bar soldering

- BGA Assembly - smallest pitch .25mm

- 01005 or above - component placement

- Selective Wave Solder

- ACF/ACP bonding (anisotropic conductive film or paste bonding)

- Wire Harness - added to circuit assembly

- Sonic welding or other attachment methods and much more…

- FCT will also design and procure specialized equipment to support overall program requirements if/as needed and more…

Today, above 65% of the products that we produce are circuit assemblies; whereby we are placing components onto the flex/rigid flex/flex heaters that we produce and/or taking the product further in producing a product module or complete product box build.

FCT is one of the most proficient "assembly on flex" companies on the globe, offering years of proven expertise.

Why more customers are utilizing FCT's assembly services…

FCT maximizes value in providing cost effective assemblies to our customers.

- We provide overall program management inclusive of procuring and managing the components and overall supply chain.

- If we are already building your circuit, it would make great sense to simply have us perform your Assembly service.

- Panelization - FCT maximizes the number of circuits per panel to assure we maximize material costs and have as little waste of material as possible, leading to lower overall circuit cost.

- We do not place unrealistic x-out requirements on our panels that lead to higher costs for the end customer; something that outside assembly shops may require.

- By maximizing the number of parts per panel and by not putting phantom x-out requirements on the panels - FCT can provide cost effective circuit assembly solutions for our customers.

- Further, our proven expertise in assembly on flex will lead to higher yields, again leading to improved savings for our customers.

We would welcome the opportunity of taking your circuit further by supporting you with our EMS/Assembly services!

Product Module to Complete Product Box Build Services

Our customers continue to demand more and FCT has responded to where today we provide customers with added service in delivering Product Module Builds to Complete Box Builds. It was a natural step for us given we were often producing an assembly that would be at the heart of a Product Module or in cases of the overall Product or Device.

For Product Module builds most often this includes taking the circuit assembly and providing additional value-added assembly, it could be that we are attaching it to a plastic carrier or metal component. It could be that we are adding an additional component or wire harness and then shipping the product module to our customer for input into the OEM's final product.

For complete Product Box Builds, FCT takes on the entire product program for our customer. Most often this includes producing and testing the circuit assembly that is at the core of the product. We then utilize our plastics group to produce a housing or carrier if needed. Our test engineering team will load firmware and develop test processes and procedures to meet customer requirements. We also will source any additional items or components required through our ISO approved sub-suppliers.

FCT also takes on Medical related programs that require FDA product registration. To meet FDA requirements, FCT must have robust quality systems in place and further must be able to meet the stringent traceability requirements that these program demand.

FCT Box Build Services include:

- Core electronics – Flex/Rigid Flex/Flexible Heater/Membrane Switch and full Assemblies

- Testing Services for circuit assemblies

- Sub-Level Product Assembly, Product Module Builds and Testing

- Sourcing of specialized materials and/or components

- Complete Product Assembly

- Software Loading and Product Configuration

- Final Product Testing Services

- Documentation Inclusion and traceability requirements

- Packaging and Labeling

- Warehousing and Shipping

- Overall Program Management

FCT has performed Product Module/Complete Box Build services for start-ups, to mid-sized growth companies, to top tier global OEMs in the differing markets that we support.

FCT Certifications can be found in the Certification links below.