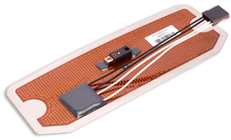

Flexible Heaters

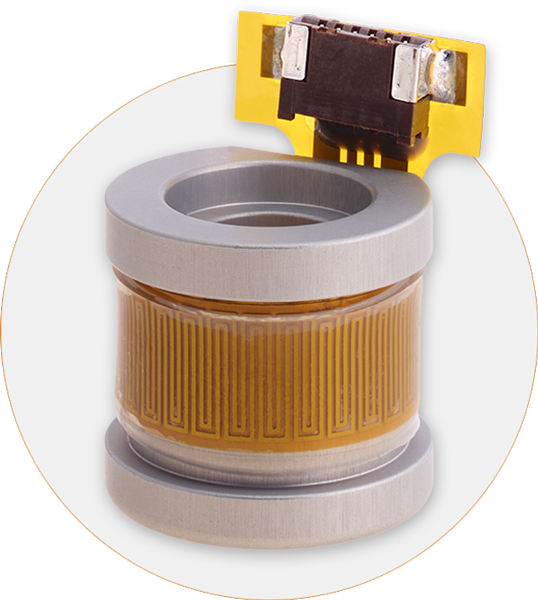

Flexible heaters are typically single layer flexible circuits that utilize copper or resistive alloys, such as Inconel and Cupro-nickel, to form conductive paths. As electrical current is driven through the higher resistance conductors, heat is generated. Conductor width and thickness are selected to provide the desired resistance value based on the supply voltage. Dielectric materials are selected based on operating temp and heater power density.

Flexible Circuit Technologies, a premier global supplier in design and production of

Flexible Circuits, Rigid Flex, Flexible Heaters, Flat Flex Cables, Membrane Switches, Plastic Moldings, Assemblies, Product Module Builds to Complete Product Box Builds

For more in depth information on Flexible Heaters, click on the links below:

In summary, if you have flexible circuit design or flexible printed circuit board needs, we can help.